1. Tiknoolajiyada asalka ah

Waqtigan xaadirka ah, nidaamyada WIM ee ku saleysan piezoelectric quartz dareemayaasha ayaa si weyn loogu isticmaalaa mashaariicda sida la socodka culeyska xad dhaafka ah ee buundooyinka iyo godadka, xoojinta culeyska xad dhaafka ah ee aan goobta ahayn ee baabuurta xamuulka ah ee wadooyinka, iyo xakamaynta culeyska tignoolajiyada. Si kastaba ha ahaatee, si loo hubiyo saxnaanta iyo nolosha adeegga, mashaariicda noocan oo kale ah waxay u baahan yihiin dib-u-dhiska sibidhka sibidhka ee quartz piezoelectric oo miisaankeedu yahay aagga rakibaadda dareenka ee heerka tignoolajiyada hadda. Laakiin meelaha qaar ee codsiyada, sida buundooyinka buundooyinka ama waddooyinka magaalada oo leh cadaadis baabuur oo culus (halkaas oo wakhtiga daaweynta sibidhka uu aad u dheer yahay, taasoo ka dhigaysa xiritaanka waddooyinka muddada dheer adag), mashaariicda noocan oo kale ah way adagtahay in la fuliyo.

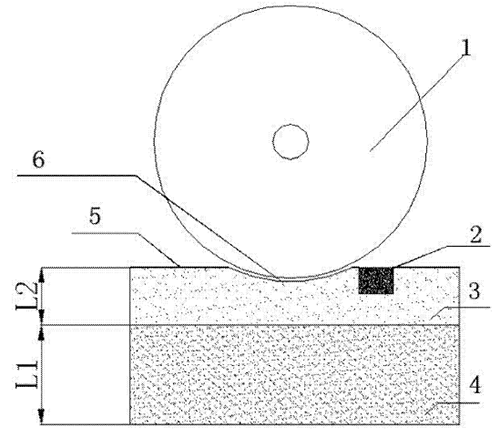

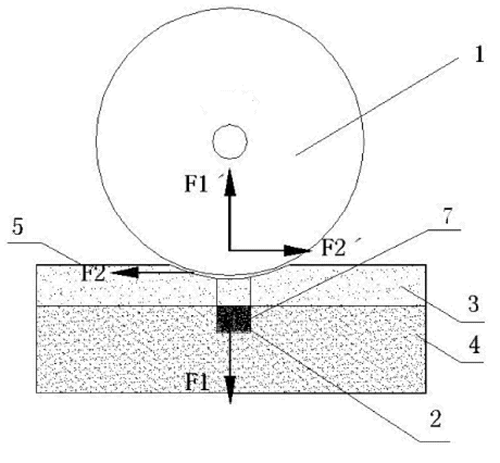

Sababta dareemayaasha miisaaman ee quartz piezoelectric aan si toos ah loogu rakibi karin laami dabacsan waa: Sida ku cad sawirka 1, marka giraangiraha (gaar ahaan culeys culus) uu ku socdo laamiga dabacsan, oogada wadada waxay yeelan doontaa hoos u dhac weyn. Si kastaba ha ahaatee, marka la gaaro piezoelectric quartz adag ee aagga dareeraha miisaamaya, sifooyinka hoose ee dareemayaasha iyo aagga interface laami way kala duwan yihiin. Waxaa intaa dheer, dareemaha miisaanka adagi ma laha dhejis toosan, taas oo keenaysa dareenka miisaanku inuu si dhakhso ah u jebiyo oo ka sooco laamiga.

(1-wheel, 2-dareemaha miisaanka, 3-jilicsan lakabka saldhiga, 4-lakab saldhig adag, 5-laami dabacsan, 6-meel hoosaad, 7-xumo suuf)

Sababo la xiriira sifooyinka hoose ee kala duwan iyo isugeynta is jiid jiidka laamiga ee kala duwan, baabuurta dhex mareysa dareemaha miisaamaya piezoelectric quartz waxay la kulmaan gariir aad u daran, taasoo saameyn weyn ku leh guud ahaan saxnaanta miisaanka. Ka dib cadaadiska muddada dheer ee baabuurta, goobta waxay u nugul tahay waxyeello iyo dildilaac, taasoo keenta dhaawaca dareemayaasha.

2. Xalka Hadda ee Goobtan: Dib-u-dhiska Laamida Lamka ah ee Sibidhka

Dhibka ay leedahay dareemaha miisaamaya piezoelectric quartz oo aan awoodin in si toos ah loogu rakibo laamiga asphalt, cabirka baahsan ee laga qaatay warshadaha ayaa ah dib u dhiska laami sibidhka ah oo loogu talagalay aagga rakibaadda dareemayaasha piezoelectric quartz. Dhererka dib-u-dhiska guud waa 6-24 mitir, oo ballaciisu le'eg yahay ballaca waddada.

Inkasta oo dib-u-dhiska laamida sibidhka ah uu buuxiyo shuruudaha xoogga leh ee lagu rakibo piezoelectric quartz miisaannada dareemayaasha iyo hubinta nolosha adeegga, arrimo dhowr ah ayaa si ba'an u xannibaya dhiirrigelinteeda baahsan, gaar ahaan:

1) Dib-u-dhiska adag ee sibidhka ee ballaadhan ee laamigii asalka ahaa wuxuu u baahan yahay kharash badan oo dhismaha ah.

2) Dib-u-dhiska sibidhka sibidhka wuxuu u baahan yahay waqti dhisme oo aad u dheer. Muddada daaweynta ee laamiga sibidhka oo keliya waxay u baahan tahay 28 maalmood (shuruudaha caadiga ah), taas oo shaki la'aan saameyn weyn ku leh ururinta taraafikada. Gaar ahaan xaaladaha qaarkood ee nidaamyada WIM ay lagama maarmaan u yihiin laakiin socodka taraafikada goobta uu aad u sarreeyo, dhismaha mashruucu inta badan waa adag yahay.

3) Burburinta qaab dhismeedka wadada asalka ah, saameynaya muuqaalka.

4) Isbeddellada degdega ah ee isku-dhafka is-burburku waxay sababi karaan ifafaale is-dhaafitaan ah, gaar ahaan xaaladaha roobabka, kuwaas oo si fudud u horseedi kara shilal.

5) Isbeddelka ku yimaadda qaab dhismeedka waddooyinku waxay sababaan gariir baabuurka, kaas oo saameeya saxnaanta miisaanka ilaa xad.

6) Dib u dhiska shubka sibidhka laguma hirgelin karo waddooyin gaar ah, sida buundooyinka dhaadheer.

7) Waqtigan xaadirka ah, dhinaca isu socodka waddooyinka, waxay u socdaan caddaan ilaa madow (laami sibidh ah oo loo beddelayo laami). Xalka hadda jira waa madow ilaa caddaan, taas oo aan ku habboonayn shuruudaha ku habboon, iyo qaybaha dhismaha ayaa inta badan u adkaysta.

3. Mawduuca Rakibaadda oo la hagaajiyay

Ujeedada qorshahan waa in la xalliyo yaraanta dareemayaasha miisaamaya piezoelectric quartz oo aan awoodin in si toos ah loogu rakibo laamiga shubka ah ee asphalt.

Nidaamkani wuxuu si toos ah u dhigayaa dareemaha miisaanka quartz piezoelectric ee lakabka aasaasiga ah ee adag, isaga oo ka fogaanaya arrin la'aanta muddada dheer ee ay sababtay isku-dhafka tooska ah ee qaab-dhismeedka dareemayaasha adag ee laami dabacsan. Tani waxay si weyn u kordhisaa nolosha adeegga waxayna hubisaa in saxnaanta miisaanku aanay saameyn ku yeelan.

Intaa waxaa dheer, looma baahna in dib-u-dhiska sibidhka sibidhka lagu sameeyo laamigii asphalt ee asalka ahaa, badbaadinta qadar badan oo kharashka dhismaha ah oo si weyn u gaabinaya muddada dhismaha, taas oo bixisa suurtogalnimada kor u qaadida ballaaran.

Jaantuska 2 waa jaantus jaantus ah oo qaab-dhismeedka ah oo leh dareemaha miisaanka quartz piezoelectric oo lagu dhejiyay lakabka hoose ee jilicsan.

(1-wheel, 2-dareemaha miisaanka, 3-jilicsan lakabka saldhiga, 4-lakab saldhig adag, 5-laami dabacsan, 6-meel hoosaad, 7-xumo suuf)

4. Farsamooyinka Muhiimka ah:

1) Qodista ka-hortagga ka-hortagga qaab-dhismeedka saldhigga si loo abuuro booska dib-u-dhiska, oo leh qoto dheer oo ah 24-58 cm.

2) Heerarka hoose ee booska iyo ku shubista walxaha buuxinta. Saamiga go'an ee ciid quartz + ahama birta ciid epoxy resin ayaa lagu shubay gunta hoose ee booska, si siman u buuxsamay, oo leh qoto dheer buuxinta 2-6 cm oo la simay.

3) Ku shubida lakabka hoose ee adag iyo rakibida dareeraha miisaanka. Ku shub lakabka adag oo ku dheji shidma miisaanka, adoo isticmaalaya suufka xumbo (0.8-1.2 mm) si aad u kala soocdo dhinacyada dareenka miisaanka iyo lakabka adag ee salka. Ka dib markii lakabka saldhiga adag uu adkeeyo, isticmaal Furimaha Dagaalka si aad u shiido dareeraha miisaanka iyo lakabka adag ee saldhiga isla diyaarad. Lakabka salka adag wuxuu noqon karaa mid adag, badh-adag, ama lakabka hoose ee isku dhafan.

4) Ku shubida lakabka dusha sare. Isticmaal walxaha ku habboon lakabka saldhigga dabacsan si aad u shubto oo aad u buuxiso dhererka haray ee booska. Inta lagu jiro habka shubista, isticmaal mishiinka yar yar si aad si tartiib ah isugu dhejisid, hubinta heerka guud ee dusha sare ee dib loo dhisay ee wadooyinka kale. Lakabka salka dabacsan waa lakabka sare ee asphalt granular dhexdhexaad ah.

5) Saamiga dhumucda lakabka salka adag ee lakabka dabacsan waa 20-40: 4-18.

Hal qayb oo ka mid ah Enviko Technology Co., Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Xafiiska Chengdu: No. 2004, Cutubka 1, Dhismaha 2, No. 158, Tianfu 4th Street, Hi-tech Zone, Chengdu

Xafiiska Hong Kong: 8F, Cheung Wang Building, 251 San Wui Street, Hong Kong

Warshada: Dhismaha 36, Aagga Warshadaha ee Jinjialin, Magaalada Mianyang, Gobolka Sichuan

Waqtiga boostada: Abriil-08-2024