Iyada oo ay kordheyso baahida loo qabo la socodka culeyska waddooyinka iyo buundada ee maamulka taraafikada casriga ah, tignoolajiyada Miisaanka-In-Motion (WIM) ayaa noqotay aalad lagama maarmaan u ah maareynta taraafikada iyo ilaalinta kaabayaasha. Alaabta dareemayaasha quartz ee Enviko, oo leh waxqabadkooda ugu wanaagsan iyo isku halaynta, ayaa si weyn loogu dabaqay nidaamyada WIM.

Mabaadi'da Quartz Miisaanka-In-Motion (WIM) Algorithms

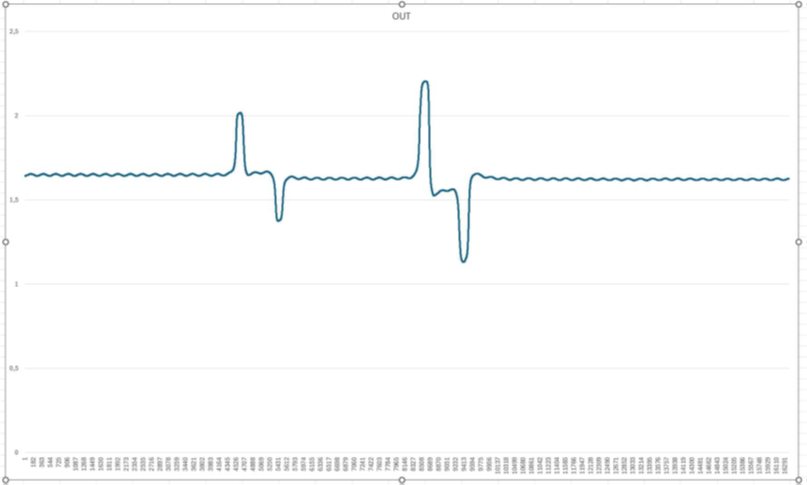

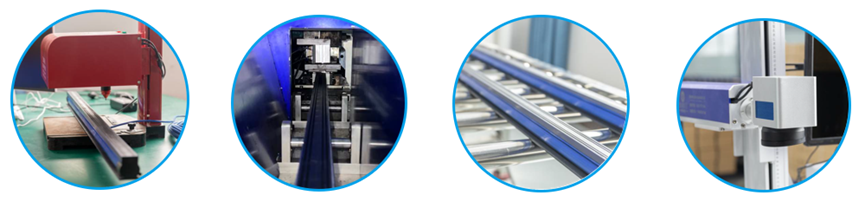

Xudunta nidaamka Miisaanka Quartz-ku-In-Motion (WIM) waa in la cabbiro cadaadiska ay ku samaynayaan dusha sare ee baabuurtu wakhtiga dhabta ah iyadoo la isticmaalayo dareemayaasha quartz ee lagu rakibay wadada. Dareemayaasha Quartz waxay isticmaalaan saamaynta piezoelectric si ay calaamadaha cadaadiska ugu beddelaan calaamadaha korantada. Calaamadaha korantada waa la xoojiyay, la sifeeyay, iyo digitized, ugu dambeyntiina waxaa loo isticmaalaa in lagu xisaabiyo miisaanka gaariga.

Dareemayaasha Quartz ee Enviko ee lagu dabaqay nidaamyada WIM waxay leeyihiin dareen sare iyo sifooyin jawaab celin ballaaran, taasoo u sahlaysa inay si sax ah u qabtaan isbeddelada cadaadiska isla markiiba marka baabuurtu dul maraan. Intaa waxaa dheer, dareemayaasha quartz waxay leeyihiin xasillooni heerkul aad u fiican iyo nolol dheer, iyagoo ilaalinaya waxqabadka xasilloon ee deegaanno kala duwan oo adag.

Talaabooyinka Algorithmka Miisaanka-In-Motion (WIM).

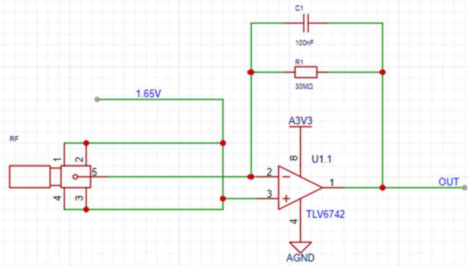

1.Helitaanka ishaarkaQabo calaamadaha cadaadiska ee ay sameeyaan gawaarida adoo isticmaalaya dareemayaasha quartz, u beddela calaamadahan calaamadaha korantada una gudbiya nidaamka helitaanka xogta.

2.Kordhinta Calaamadaha iyo Shaandhaynta: Kordhi oo kala shaandhsii calaamadaha korantada ee la helay si aad meesha uga saarto buuqa iyo faragelinta, adigoo haysanaya macluumaadka miisaanka waxtarka leh.

3.Digitization DataU beddel calaamadaha analoogga oo u beddelo calaamadaha dhijitaalka ah si loo habeeyo iyo falanqaynta dambe.

4.Sixitaan salkaSamee sixitaanka asaasiga ah ee calaamadaha si aad meesha uga saarto culeyska eber, hubinta saxnaanta cabbirka.

5.Habaynta is dhexgalkaIsku dhafka calaamadaha saxda ah waqti ka dib si aad u xisaabiso wadarta kharashka, taas oo u dhiganta miisaanka baabuurka.

6.CalibrationIsticmaal qodobbada hagaajinta ee horay loo go'aamiyay si aad ugu beddesho wadarta kharashka qiyamka miisaanka dhabta ah.

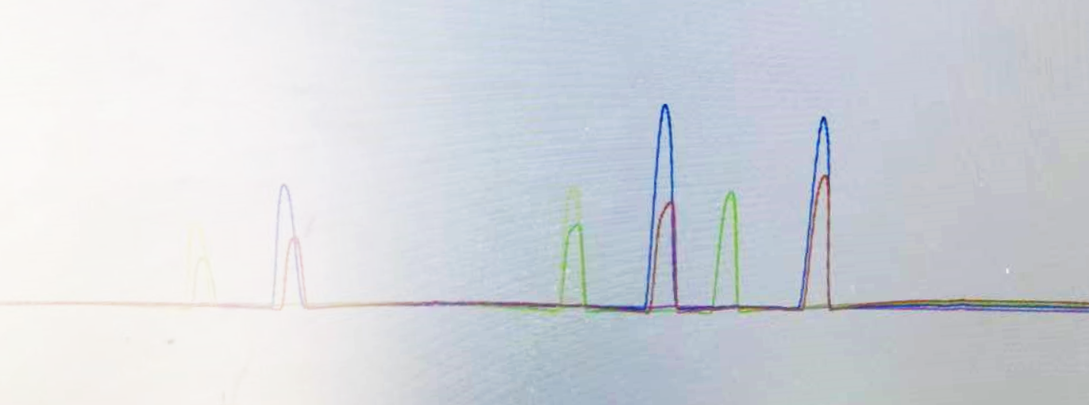

7.Xisaabinta Miisaanka: Haddii dareemeyaal badan la isticmaalo, ku soo ururi miisaannada dareemaha kasta si aad u hesho wadarta miisaanka baabuurka.

Xiriirka ka dhexeeya Algorithms iyo Saxnimada

Saxnaanta nidaamka Miisaanka-In-Motion (WIM) waxay inta badan ku xiran tahay algorithms-yada la isticmaalo. Dareemayaasha Quartz ee Enviko waxay xaqiijiyaan saxnaanta cabbiraadda miisaanka iyada oo loo marayo helitaanka calaamadaha saxda ah ee saxda ah iyo habaynta. Saxnaanta iyo hufnaanta algorithms-ka habaynta xogta waxay si toos ah u saameeyaan natiijooyinka miisaannada ugu dambeeya. Habaynta calaamadaha horumarsan iyo algorithms falanqaynta xogta waxay si wax ku ool ah u wanaajin karaan saxnaanta miisaanka waxayna yareeyaan khaladaadka cabbirka.

Gaar ahaan, saxnaanta helitaanka calaamadda, waxtarka shaandhaynta dhawaaqa, iyo saxnaanta hababka isdhexgalka iyo habaynta ayaa ah qodobbada muhiimka ah ee saameeya saxnaanta miisaamidda. Dareemayaasha Quartz ee Enviko ayaa aad uga sarreeya meelahan, iyaga oo hubinaya saxnaanta sare iyo isku halaynta nidaamyada WIM iyada oo loo marayo algorithms horumarsan iyo qalab tayo sare leh.

Xiriirka ka dhexeeya Rakibaadda iyo Xaqiijinta

Goobta rakibaadda iyo habka dareemayaasha quartz waxay si weyn u saameeyaan saxnaanta cabbirka nidaamka WIM. Dareemayaasha waa in lagu rakibaa meelaha muhiimka ah ee wadada baabuurka si loo hubiyo qabashada saxda ah ee isbedelka cadaadiska ugu badan. Inta lagu jiro rakibidda, waxaa lagama maarmaan ah in la hubiyo xiriirka dhow ee u dhexeeya dareemayaasha iyo dusha wadada si looga fogaado khaladaadka cabbirka sababtoo ah rakibid aan habboonayn.

Intaa waxaa dheer, arrimaha deegaanka sida heerkulka, qoyaanka, iyo dhullanaanta ayaa sidoo kale saameyn ku yeelan kara waxqabadka dareemayaasha iyo saxnaanta cabbirka. In kasta oo dareemayaasha Quartz ee Enviko ay leeyihiin xasillooni heerkuleed oo heer sare ah, tallaabooyinka magdhowga habboon ayaa weli looga baahan yahay xaaladaha heerkulka aadka u daran si loo xaqiijiyo natiijooyinka cabbirka saxda ah.

Qalabaynta joogtada ah iyo dayactirka ayaa sidoo kale lama huraan u ah si loo xaqiijiyo hawlgalka xasilloon ee muddada dheer ee dareemayaasha. Iyada oo loo marayo rakibaadda xirfadleyda iyo dayactirka, waxqabadka dareemayaasha Enviko quartz waa la kordhin karaa, iyadoo la siinayo xog sax ah oo la isku halayn karo oo miisaan firfircoon (WIM).

Gabagabo

Codsiga dareemayaasha Enviko's quartz ee hababka miisaamidda firfircoon (WIM) waxay bixisaa xalal hufan oo la isku halayn karo oo loogu talagalay maareynta taraafikada iyo ilaalinta kaabayaasha. Iyada oo loo marayo helitaanka calaamadaha saxda ah, farsamaynta algorithm horumarsan, iyo rakibida iyo dayactirka xirfadlayaasha ah, nidaamyada miisaamidda firfircoon ee quartz (WIM) waxay gaari karaan la socodka waqtiga-dhabta ah iyo maareynta miisaanka gaariga, si wax ku ool ah u yareeya jeexjeexa iyo jeexjeexa buundada iyo hagaajinta hufnaanta maareynta taraafikada. Horumarka tignoolajiyada ee joogtada ah, dareemayaasha Enviko quartz waxay ka ciyaari doonaan door muhiim ah oo sii kordheysa nidaamyada WIM, iyagoo siinaya aasaas adag oo loogu talagalay horumarinta gaadiidka caqliga leh.

Hal qayb oo ka mid ah Enviko Technology Co., Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Xafiiska Chengdu: No. 2004, Cutubka 1, Dhismaha 2, No. 158, Tianfu 4th Street, Hi-tech Zone, Chengdu

Xafiiska Hong Kong: 8F, Cheung Wang Building, 251 San Wui Street, Hong Kong

Waqtiga boostada: Agoosto-07-2024